Quality and Innovation

Quality for us, means innovation, both are part of the historical course of business development

The company has consolidated skills and knowledge that can help you meet quickly all the requirements of the most demanding customers excellent quality for all kinds of construction, using highly qualified personnel and a flexible organization able to respond to the constant developments demanded by the market not only in production field; but also in terms of the service provided.

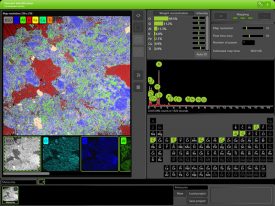

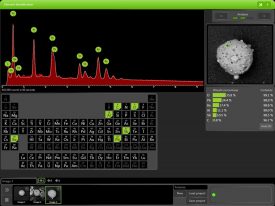

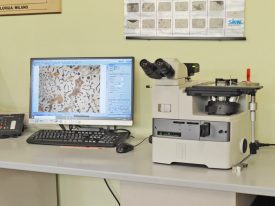

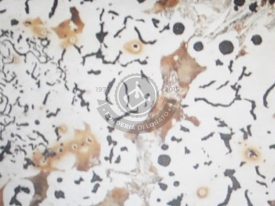

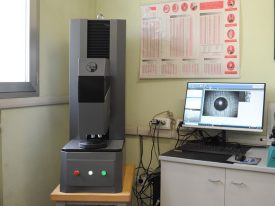

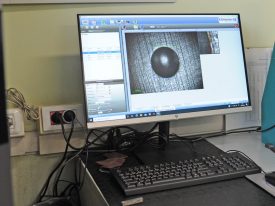

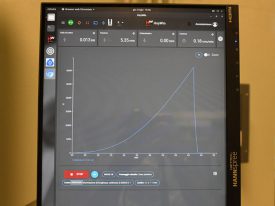

The practice of quality begins with the assessment of the request of potential customers through analysis of feasibility, process control plan, that will oversee the production cycle monitoring until final inspection Product, with its issuance of inspection certificates. The stages of product development are: sampling, pre-series and series production.

Each batch is identified with a casting number allowing traceability. The control of each stage of the process is carried out by qualified technical employees, in accordance with the technical standards and procedures.

The support activities, carried out in close collaboration with the customer, it is essential to get the best results in terms of product quality and customer satisfaction.

Fonderia di Lonato is certified UNI-EN-ISO 9001:2015 not only for production but also for the design of castings.